Flexytote

Flexible multi-totes transfer solution for your warehouse

Flexytote® provides an alternative

to traditional logistics systems.

It flexibly automates totes transfer operations in warehouses to accelerate multi-order picking.The principle : a mobile robot lifts and moves empty totes or boxes to the order buffer racks for picking.

Operators complete the orders, then when the totes/boxes are full,

the robot transfer them to the packing area. The Flexytote® solution extends

the Scallog range, delivering

unrivalled flexibility and ROI.

Unlike a typical conveyor, Flexytote® makes it very

simple and easy to automate supply to 2-or 3-level order buffer racks.

1

Transporting

empty totes

2

Totes loaded

in the order buffer rack

3

Totes filled

by operators

4

Transporting full

order totes

5

Full totes removed to the consolidation or packaging area

Example of a workstation

Flexible

Flexytote® is the key to versatility : this flexible, scalable

transport system follows optical marking on the floor and

does not require complex installation, its layout can be

reconfigured as and when required.

The system management software is simple, quick to install

and can be tailored to meet the requirements of your

changing environment.

Robot

Unprecedented modularity and flexibility in the automation

of totes supply and transfer operations. Multi-totes robots

with fork blades and loads that can be configured

on 2 or 3 levels.

- Dimensions : 800 x 600 mm

- Maximum load : 250 kg

- Battery life : 14 hrs

- Communication : WIFI

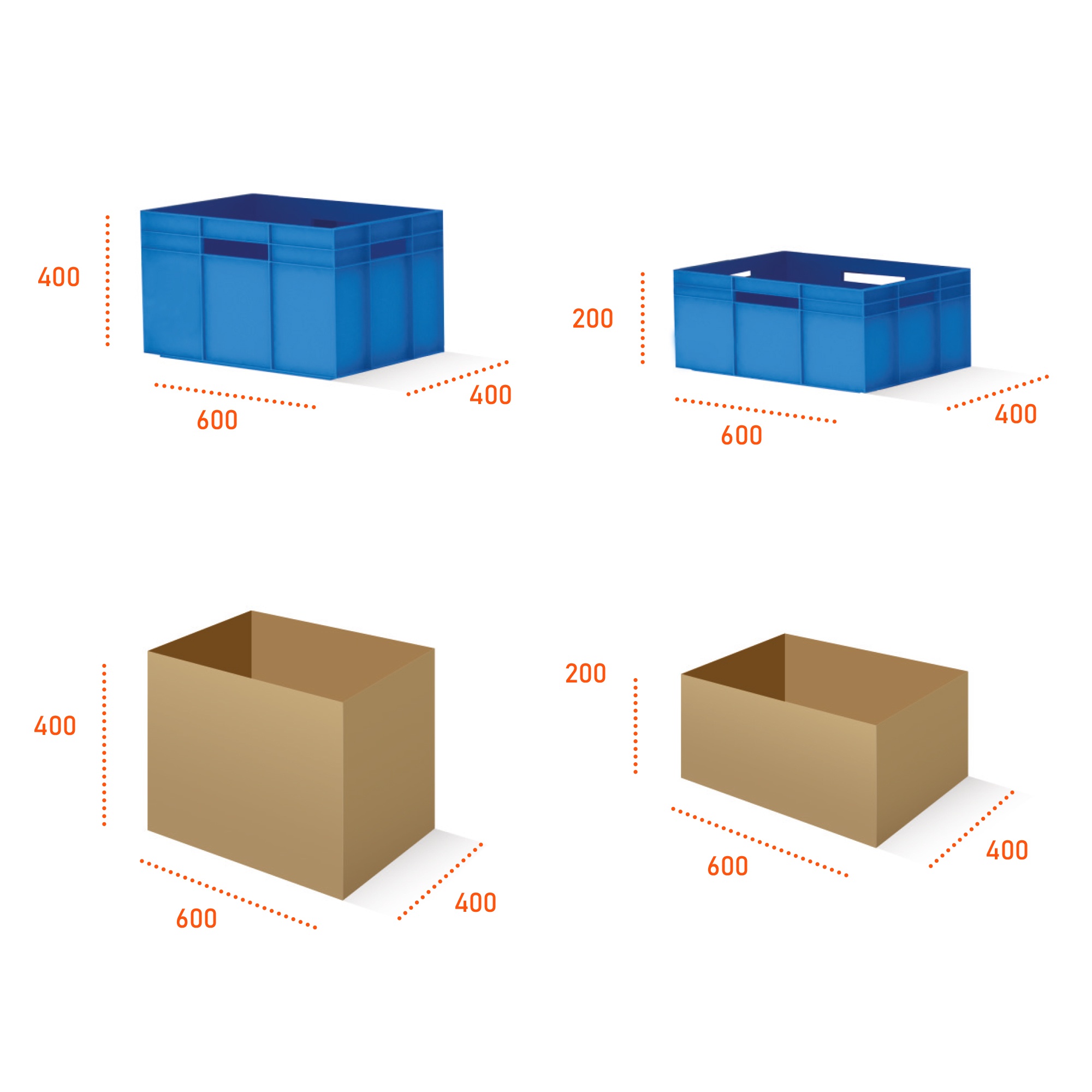

Totes

Size of storage locations can be

changed and dynamically adjusted.

No storage positions assigned

permanently.

Fork blades configuration

• 2 levels : 2 x 4 totes

(max. 30 kg / bin)

• 3 levels : 2 x 6 totes

(max 20 kg / bin)

Totes configuration

• 2 levels : 4 totes

• 3 levels : 6 totes

Applications

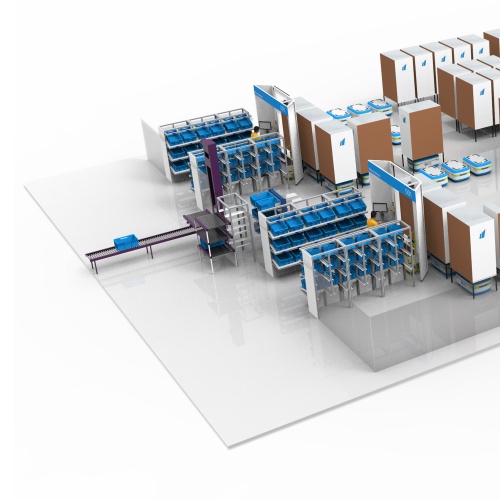

Micro Fullfilment Center

The Flexytote® gives you a wide range of possibilities for the automated transport

of orders in production or operations

- Extremely simple to manage

- Flexible, can be adapted to growing needs

- Efficient internal transport

- More than one destination can be assigned

- Decrease in staff movement, the system

is working in background tasks

• Totes (600 x 400 x 200)

• 36 Totes / workstation

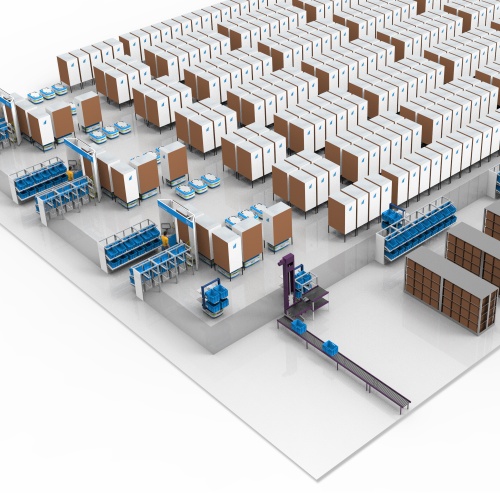

Fast - Growing Warehouse

The Flexytote® adapts to the evolution of your warehouse : easy connection to already existing systems thanks to automatic transfer units

- Automatic loading of totes

- Integration into existing solutions

- Workstation ergonomics

- Operators no longer have to carry order totes

• Totes (600 x 400 x 300)

• 24 totes / workstation

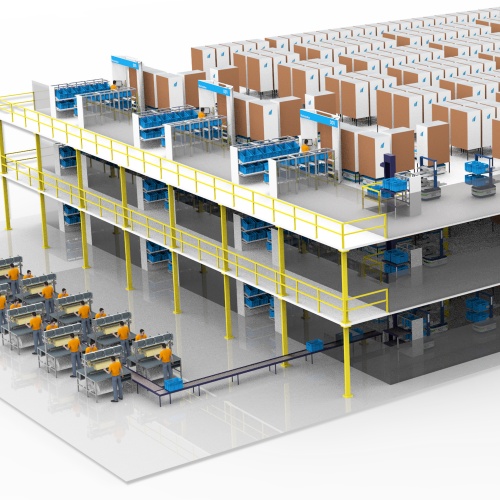

High density & Multi-levels

The Flexytote® can interface to a lifting solution

allowing to link different levels for multi-platform flows

- Products can be sequenced by family

- Automatic management of loading

- Connection to existing product flow systems

- Fleet of robots used on different levels

Benefits

Fast implementation

Not permanently

anchored to the floor

Easy management

of peaks in activity

Minimal use

of conveyors

Easy sequencing of

goods to be transported

Transport solution with

unrestricted access in a

reduced area

Simplified maintenance

Autonomous navigation

Integration into

existing systems

Great flexibility in

tailoring and extending

the system

Rapid ROI

Managed by WiFi

Different construction

heights for best

ergonomics

Synchronization with

internal order flows