Inventory

Function

Inventory counts consist of counting, identifying and recording all the elements of an inventory holding. They are used to:

- Calculate the variation in inventory between the beginning and end of a financial year. In this specific case, inventory counts are mandatory.

- Organizing order picking.

- Managing supplies in the logistics chain.

The continuous inventory count is a process that records incoming and outgoing movements. It provides a continuous record of the quantities and values of current inventory.

Managing the referencing and monitoring of stored and non-moving products has an economic and organizational impact on your company’s performance.

Inventory counts are central to a company’s strategy, key factors in its performance.

Scallog application

Generally, inventory counts require the total or partial interruption of a company’s activity.

With the Scallog solution, your inventory counts are undertaken in real time on a paperless basis. Scanning items as they come into, and go out of, inventory automatically updates the item database of your inventory in your ERP or WMS system.

The power and flexibility of our solution meets the complex requirements of executing and managing your inventory. You can at any time:

- See your inventory variations.

- Anticipate replenishment.

- Feed back any anomalies observed (errors in quantity or product storage).

- Undertake inventory audits.

- Reposition inventory in real time for optimal use of space.

- Record shelf storage locations.

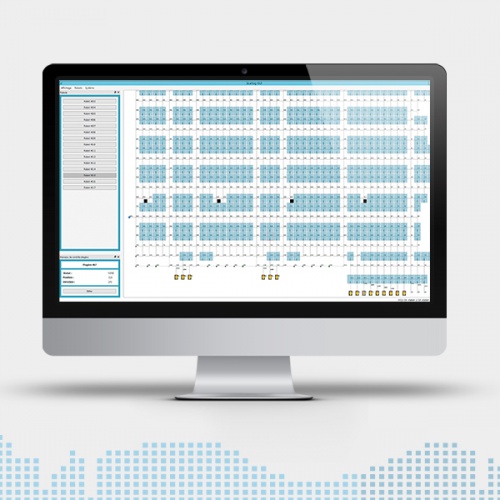

Scallog System TM Software

Our Scallog System TM software handles a multitude of inventory management strategies and adapts intelligently in real time to changes in inventory profiles.

It will give you better visibility, positional accuracy and inventory trackability.

The Scallog inventory software can be used as a tool for management control, rationalizing purchases and leveraging maintenance operation performance. It will enable you to rationalize your processes, optimize your costs and gain in productivity.

Did you know that our Spot-to-light technology increases operator productivity by 40%?