Manufacturing

Manufacturing challenges

Manufacturing businesses face many challenges when it comes to optimizing logistics. Reliable picking is a prerequisite for reducing losses when picking orders for spare parts, which require a minimal reject rate due to their added value.

In a sector where increases in the production rate are forcing manufacturers to store more products in a limited area, it is becoming essential to reduce movements in warehouses and decrease handling operations.

Automated picking

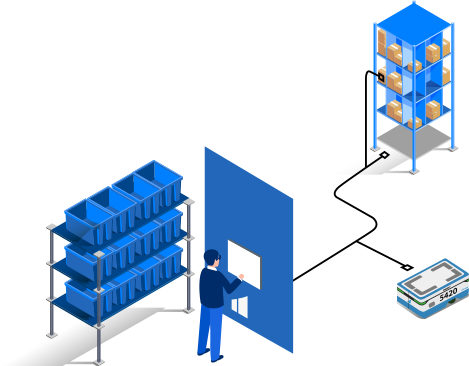

Scallog’s robotized picking solution is based on an efficient inventory and warehouse flow management system. Automation eliminates unnecessary movement in a warehouse and increases the speed and number of orders that can be picked in parallel. There is an immediate gain in speed and efficiency: with a rate of 450 to 600 picks per hour, productivity is increased threefold.

All of the systems are equipped with cutting-edge software and sensors, which ensures maximum precision and reduces the risk of your goods deteriorating.

The Scallog solution improves product picking performance and reliability through the exclusive Spot-to-Light technology, which increases operator productivity by 40% and reduces the risk of error.

References

Scallog provides manufacturers with a robotized picking solution to ensure optimal management of increases in their production rate.

Assure your picking operations with Scallog, contact our team!